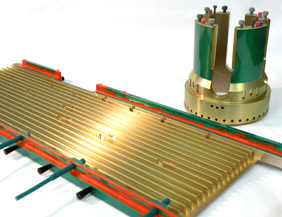

MIL offers numerous metal finishing processes. These methods improve the surface finish of a material. After finishing, parts may have improved performance in specific environments, abrasion resistance, color dyes, etc.

Metal Finishing improves the material’s surface finish.

Parts may require paint, tape, and plugs to mask areas before processing

Stay in the know with all things MIL.

Sign up for our email list for updates.

Search our approvals